Nomadory

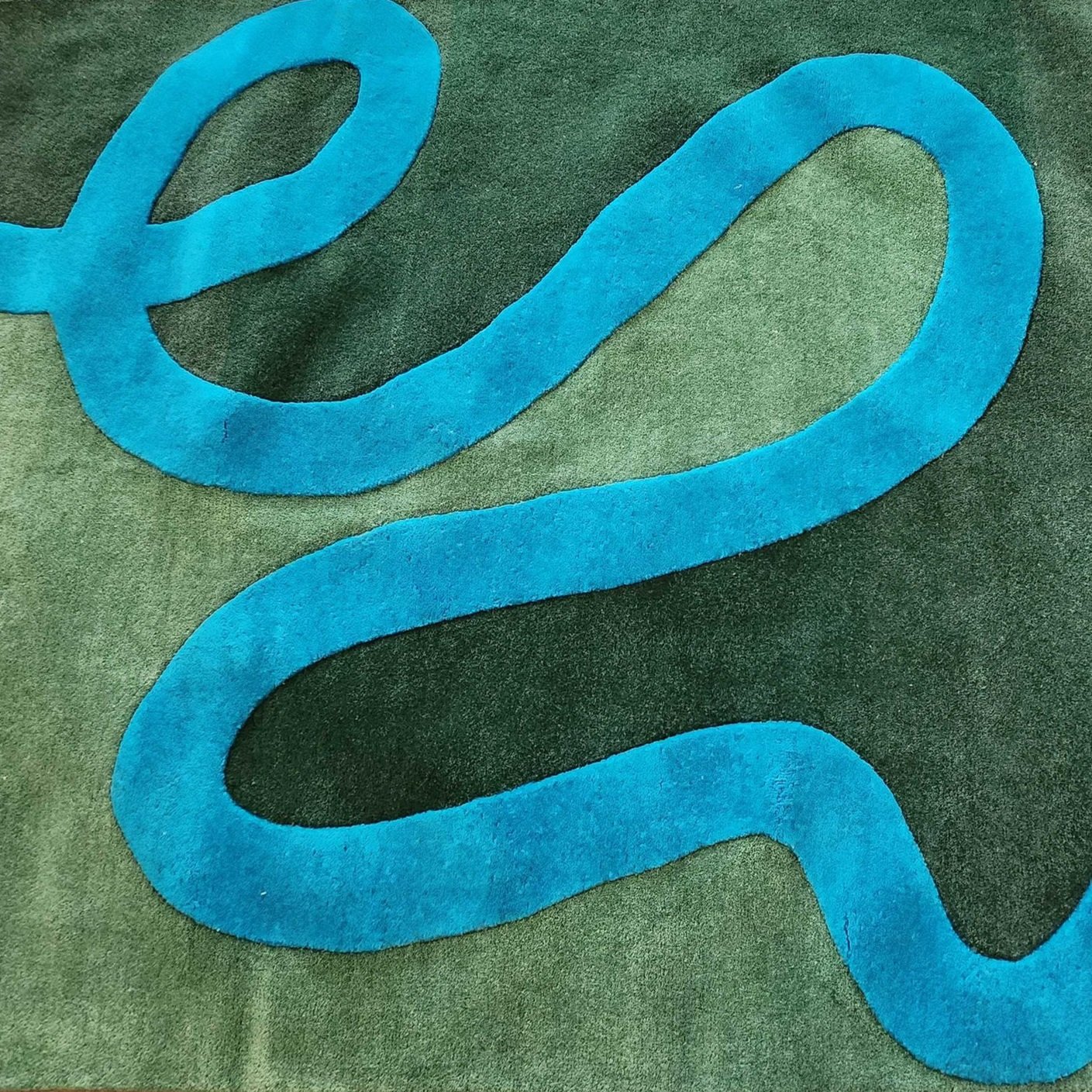

Unique, easily traceable rugs handmade by highly-skilled weavers and artisans. The perfect addition to set the mood for any space.

About

Founder: Akta Adani & Vrnda Dalal, 2019

Headquarters: San Francisco, CA

Manufacturing + Production: Bhadohi, India

Materials:

Cotton: India

Wool: India and New Zealand

Proud members of: Female Founder Collective, Trade+Impact Association, Textile Exchange

Materials

Cotton: Based on clients’ requirements Nomadory can utilize organic cotton and GOTS certified cotton

Wool: Nomadory's wool is traceable to the source, sustainable

Linen: Breathable lightweight material made of linen flax

Upcycled denim: Excess denim strips from factories are upcycled and processed into yarn for weaving

Bamboo silk: Bio-based silk made from bamboo pulp instead of silkworms

Recycled polyester: Made from recycled PET (plastic bottles)

Jute: Fabric made from fibers of the jute plant

Strong, absorbs water readily, dries quickly, and is highly resistant to abrasion and stains

Vegetable dyes: Handmade textiles can be dyed using natural dyes (turmeric, tea, indigo)

Natural dyes: Made from natural ingredients including turmeric and tea leaf

Azo-free dyes: Free of any chemicals that may cause cancer or be dangerous for human health

Manufacturing + Production: How’s it Made?

Nomadory’s artisans use traditional techniques flatweaving, hand tufting, hand knotting, and hand braiding to create their rugs.

A 6 step process is used to transform raw undyed yarn to a final rug:

Spinning: Yarn is purchased from accredited suppliers in India. Each of the yarns are mill-spun to ensure durability and quality.

Dyeing: After the yarn is spun, it’s moved to a nearby location where it’s dyed for a color match. Then it dries in the sun for six hours.

Prepping: Most processes start on a loom at an artisan’s home where they meticulously craft each rug, based on a CAD drawing of the design.

Weaving: Hand tufted rugs start with a sheet of fabric, printed with the design. The artisan punches yarn through, tuft by tuft, to match the design.

Finishing: To finish the rug, an artisan will remove it from the loom and check it for quality details before it’s ready to ship.

Packaging: Each rug is individually wrapped for safety, with labels and tags to meet your requirements. Then it’s packed and shipped via freight.

Watch the step-by-step process and hear from the artisans here.

Production Waste

The rug making process creates water waste which Nomadory’s suppliers treat via an ETP plant. The waste water is treated to remove harmful chemicals prior to discharge. The extra rug pieces which are by-product of odd sizes are further repurposed to make smaller rug swatches.

Extra dye is saved and utilized for new production orders.

Upcycled yarn and fabric (including cotton, polyesters, leather) is used to weave new rugs and swatches. If of interest to the client, Nomadory can source from suppliers that prioritize using recycled content.

Warranty, Repairability, End of Life

1 Year Warranty on DE x Nomadory custom rugs

Organic materials cotton, wool, linen, jute, bamboo silk, and the use of natural, azo-free plant-based dyes allows for materials to be biodegradable

Packaging

Currently using polywrap, working to switch to a recyclable packaging in near future.